Two Stage Compressors

Light industrial applications | High-Pressure (HP) Cylinder | Automotive applications | Commercial uses | Light industrial applications

- Home

- Two Stage Compressor

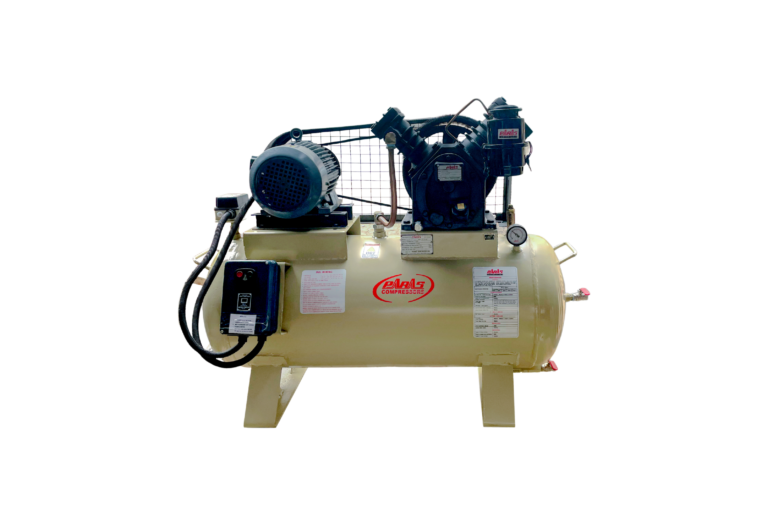

Two Stage Compressor

Two-stage compressors are built for tougher jobs, delivering significantly higher pressure than their single-stage counterparts. These workhorses feature two key components:

- Larger Low-Pressure (LP) Cylinder: This first stage efficiently draws in a greater volume of air at atmospheric pressure.

- Smaller High-Pressure (HP) Cylinder: Here, the pre-compressed air from the LP stage receives a final squeeze, reaching its designated high pressure.

The Secret’s in the Stages:

- Sequential Compression: The two-stage approach allows for efficient cooling between compression stages. This translates to cooler overall operation and less risk of carbon buildup (carbonization).

- Boosted Pressure Output: Compared to single-stage compressors, two-stage models deliver significantly higher pressure, tackling demanding tasks with ease.

- Maximized Air Delivery: The built-in intercooler plays a critical role. By effectively dissipating heat, it allows the compressor to produce more compressed air per unit of horsepower.

Perfect for Professionals:

Paras Compressor’s two-stage value-packaged air compressors are a budget-friendly choice for professionals who need a dependable air supply:

- Automotive Applications: Ensure consistent performance in body shops, tire service centers, and more.

- Commercial Users: Power a variety of tasks with reliable air pressure.

- Light Industrial Environments: Meet production demands with a dependable air source.

Our Value Package Advantage:

- Effortless Operation: Mounted and wired starter for immediate use.

- Automatic Control: Automatic start/stop pressure switch ensures efficient operation.

- Ample Storage: Suitable size receiver tank provides ample compressed air storage.

Upgrade your air power and efficiency. Contact us today to learn more about two-stage compressors!

| MODEL | MOTOR H.P | NO. OFF CYLINDER | PISTON DISPLACEMENT CFM | MAXIMUM PRESSURE PSIG | KG/CM2 | AIR RECEIVER (LITERS) |

|---|---|---|---|---|---|---|

| PC-23-234 | 2 | 2 | 7.46 | 175 | 12.3 | 150 |

| PC-23-234 | 3 | 2 | 9.74 | 175 | 12.3 | 150 |

| PC-23-242 | 5 | 2 | 17.32 | 175 | 12.3 | 200/250 |

| PC-23-253 | 7.5 | 2 | 26.4 | 175 | 12.3 | 250/300 |

| PC-23-2600 | 10 | 2 | 34.42 | 175 | 12.3 | 250/300/500 |

| PC-23-2600 | 10 | 2 | 36 | 175 | 12.3 | 250/300/500 |

| PC-23-71T2 | 10 | 2 | 40 | 175 | 12.3 | 300/500 |

| PC-23-71T2 | 12.5 | 2 | 44 | 175 | 12.3 | 300/500 |

| PC-23-71T2 | 15 | 2 | 49.5 | 175 | 12.3 | 300/500 |

| PC-23-15T | 15 | 3 | 68.15 | 175 | 12.3 | 300/500 |

| PC-23-15T | 20 | 3 | 81.8 | 175 | 12.3 | 300/500 |

| PC-23-25T2 | 20 | 3 | 82.42 | 175 | 12.3 | 500 |

| PC-23-25T2 | 25 | 3 | 104.4 | 175 | 12.3 | 500 |

| PC-23-25T2 | 30 | 3 | 115.4 | 175 | 12.3 | 500 |

| MODEL | MOTOR H.P | NO. OFF CYLINDER | PISTON DISPLACEMENT CFM | MAXIMUM PRESSURE PSIG | KG/CM2 | AIR RECEIVER (LITERS) |

|---|---|---|---|---|---|---|

| PC-23-234 | 2 | 2 | 7.46 | 175 | 12.3 | 150 |

| PC-23-234 | 3 | 2 | 9.74 | 175 | 12.3 | 150 |

| PC-23-242 | 5 | 2 | 17.32 | 175 | 12.3 | 200/250 |

| PC-23-253 | 7.5 | 2 | 26.4 | 175 | 12.3 | 250/300 |

| PC-23-2600 | 10 | 2 | 34.42 | 175 | 12.3 | 250/300/500 |

| PC-23-2600 | 10 | 2 | 36 | 175 | 12.3 | 250/300/500 |

| PC-23-71T2 | 10 | 2 | 40 | 175 | 12.3 | 300/500 |

| PC-23-71T2 | 12.5 | 2 | 44 | 175 | 12.3 | 300/500 |

| PC-23-71T2 | 15 | 2 | 49.5 | 175 | 12.3 | 300/500 |

| PC-23-15T | 15 | 3 | 68.15 | 175 | 12.3 | 300/500 |

| PC-23-15T | 20 | 3 | 81.8 | 175 | 12.3 | 300/500 |

| PC-23-25T2 | 20 | 3 | 82.42 | 175 | 12.3 | 500 |

| PC-23-25T2 | 25 | 3 | 104.4 | 175 | 12.3 | 500 |

| PC-23-25T2 | 30 | 3 | 115.4 | 175 | 12.3 | 500 |

Need more details? Contact us now

If you have any questions please contact us we will answer your questions via email as quickly as possible.