VARIABLE SPEED DRIVE SCREW AIR COMPRESSOR

Light industrial applications | High-Pressure (HP) Cylinder | Automotive applications | Commercial uses | Light industrial applications

- Home

- VARIABLE SPEED DRIVE SCREW AIR COMPRESSOR

VARIABLE SPEED DRIVE SCREW AIR COMPRESSOR

VARIABLE SPEED DRIVE SCREW AIR COMPRESSOR

Use PARAS Variable Speed Drive screw air compressor, you don’t need to worry about the complex of

electrical installation and programming for the machine. All parts of compressor are assembled before

shipment, as long as the main power supply is connected, it can work immediately.

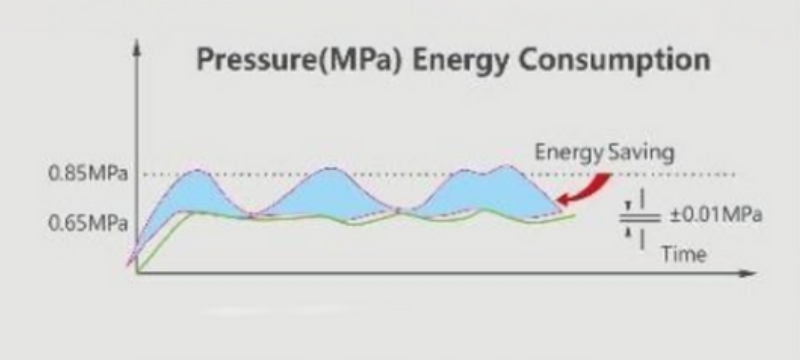

Through the powerful intelligent controller test the pressure of the air system changes continuously,

accurate to change the speed, air flow of the air compressor always consistent to the demand of the

user’s system Intelligent cantroller of reaction rate is caculated by milliseconds, and at the same time

for speed correction can be made within the 3 ms, make its outlet air pressure control within the

minimum range.

INTEL DRIVE FEATURES

High-efficiency induction motor, Integrated Variable Speed Driven (VSD) with speed control, Leading control and protection, Soft-starting eliminates drive stress.

ECONOMY OF USE

Saves your money by lowering your operation cost. These saving will continue to be delivered to your bottom line year after year.

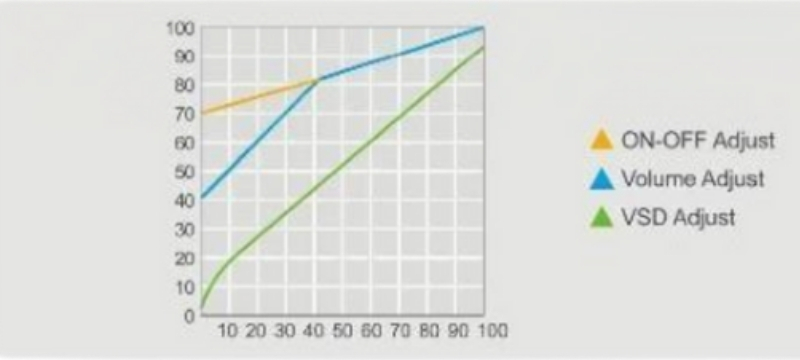

BEST EFFICIENCY AT PART-LOAD

When operating at part-load, the performance is top in class. The variable speed IntelliDriven avoids load cycling and maintains a steady state of operation, reducing operating and maintenance costs.

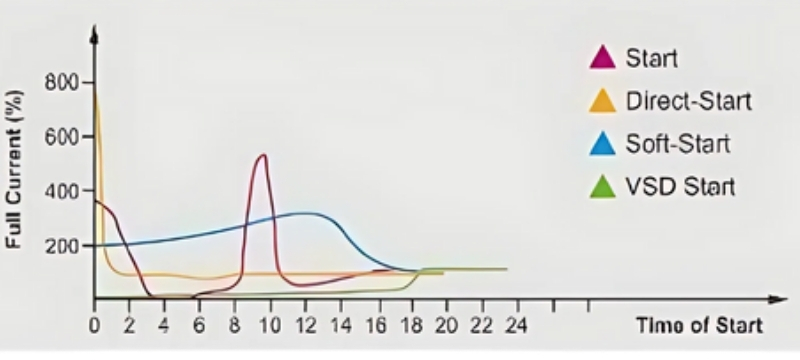

SOFT START LOWERS YOUR OPERATING COST

The gentle start cycle of the IntelliDrive increases the service life, meaning that frequent stop and restart cycles are permitted, without the risk of over-heating.

MULTIPLE MACHINE OPERATION

When operating as a pressure trim machine, the power savings achieved by a single compressor is multiplied by additional savings achieved over the full installation.

HIGH FULL-LOAD OPERATING EFFICIENCY

Class-leading performance achieved by state-of-the-art airend design and manufacturing processes, coupled with the reduction of internal losses, means that airend full-load performance.

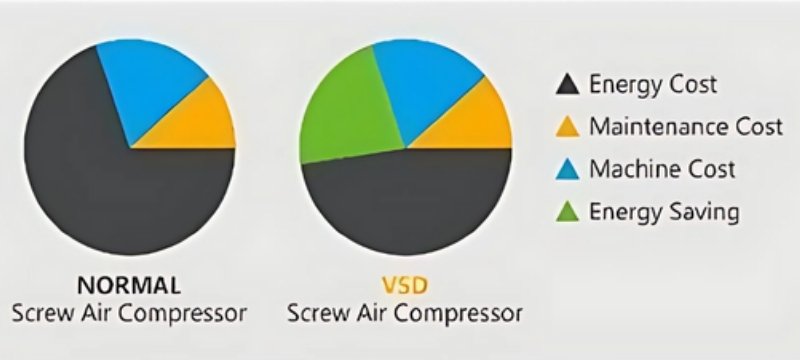

COST

The VSD screw air compressor can change the motor RPM precisely according to the air consumption under stable discharge pressure. The compressor only delivers the required air, and only consumers the energy of necessary compressed air. That’s why the VSD type screw air compressor can save energy during the whole set machine operation. The cost of saving energy is much higher than the cost of machine itself.

START AND OPERATION

The figure shows a comparison of several types of start up. We can see that the VSD air compressor is slowly accelerating started, more stable than the soft-start compressor, completely avoiding the current peak. Variable speed screw air compressor is ideal for use in areas lacking of electricity.

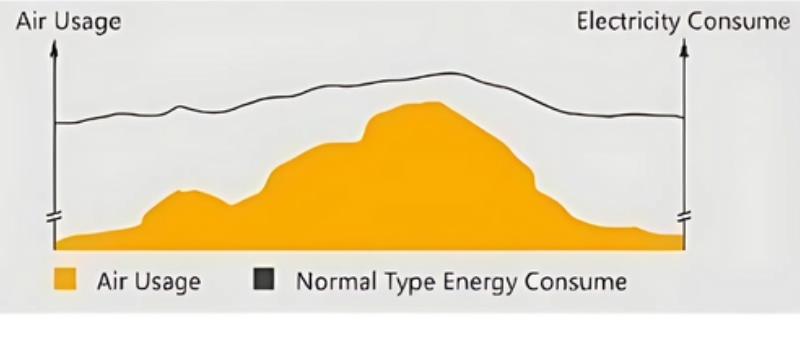

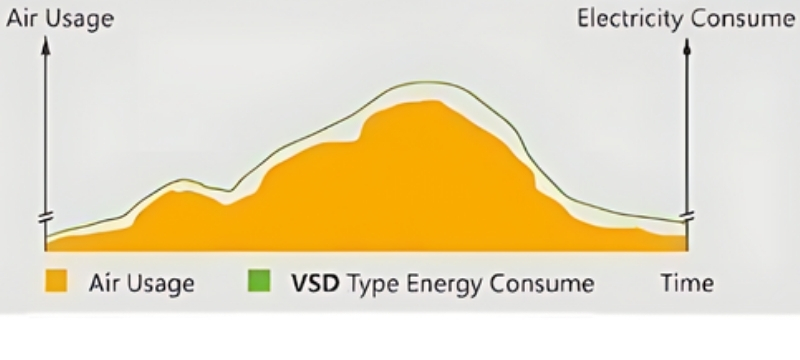

ELECTRICITY SAVING RESULT

According to the research between the VSD screw air compressor and a normal screw air compressor, there are two fields which can display the result of energy saving, the loss of no-loading and loss of fluctuating pressure. For example, for a 55KW screw air compressor, 70% air delivery in a year, the VSD type can save about 80000KWH energy. The cost of VSD can be taken back within two years.

CONSTANT PRESSURE AIR SUPPLY, WITH THE BALANCE OF PRODUCTION

The figure shows the energy consumption comparison between the general air compressor and VSD air compressor. The VSD screw air compressor changes the rotating speed according to air consumption and balance the air supply and air usage. Thus avoiding the machine frequent loading and unloading, making the VSD machine save more than 35% energy compared to normal compressor. Stable pressure delivery controlled to the pressure zone within 0.01 Mpa-0.02 Mpa, avoid energy loss under high pressure in the normal type air compressor.

TECHNICAL SPECIFICATIONS

| Model | HP | KW | Flow (7 Bar) | Flow (8 Bar) | Flow (10 Bar) | Flow (13 Bar) | Sound (dBA) | Dimensions (LxWxH) | Output Connection |

|---|---|---|---|---|---|---|---|---|---|

| PC-23-10D | 10 | 7.5 | 45 | 40 | 33 | 30 | 62±2 | 950 x 670 x 860 | G1/2" |

| PC-23-15D | 15 | 11 | 67 | 61 | 49 | 47 | 62±2 | 1050 x 700 x 1120 | G3/4" |

| PC-23-20D | 20 | 15 | 91 | 90 | 77 | 57 | 62±2 | 1050 x 700 x 1120 | G3/4" |

| PC-23-25D | 25 | 18.5 | 113 | 108 | 93 | 75 | 68±2 | 1300 x 850 x 1165 | G1" |

| PC-23-30D | 30 | 22 | 134 | 130 | 114 | 97 | 68±2 | 1300 x 850 x 1165 | G1" |

| PC-23-40D | 40 | 30 | 185 | 178 | 159 | 134 | 72±2 | 1500 x 1000 x 1300 | G1" |

| PC-23-50D | 50 | 37 | 240 | 229 | 198 | 172 | 72±2 | 1500 x 1000 x 1300 | G1 1/2" |

| PC-23-60D | 60 | 45 | 284 | 275 | 245 | 203 | 72±2 | 1500 x 1000 x 1300 | G1 1/2" |

| PC-23-75D | 75 | 55 | 380 | 360 | 318 | 300 | 75±2 | 1800 x 1250 x 1670 | G2" |

| PC-23-100D | 100 | 75 | 480 | 470 | 409 | 352 | 75±2 | 1900 x 1250 x 1670 | G2" |

| PC-23-120D | 120 | 90 | 582 | 547 | 515 | 434 | 75±2 | 2340 x 1480 x 1820 | G2" |

| PC-23-150D | 150 | 110 | 760 | 724 | 618 | 572 | 78±2 | 2568 x 1620 x 1985 | DN 65 |

| PC-23-175D | 175 | 132 | 925 | 883 | 777 | 724 | 78±2 | 2568 x 1620 x 1985 | DN 65 |

| PC-23-200D | 200 | 160 | 1013 | 974 | 868 | 759 | 79±2 | 2720 x 1750 x 2125 | DN 65 |

| Model | CAPACITY (CFM) | Working Pressure (Kg/cm²) |

|---|---|---|

| PC-23-10D | 42 | 8 |

| PC-23-20D | 90 | 8 |

| PC-23-30D | 130 | 8 |

| PC-23-40D | 178 | 8 |

| PC-23-50D | 230 | 8 |

| PC-23-60D | 276 | 8 |

| PC-23-75D | 356.73 | 8 |

| PC-23-100D | 469.75 | 8 |

| PC-23-120D | 547.46 | 8 |

| PC-23-150D | 724.06 | 8 |

| PC-23-175D | 883 | 8 |

| PC-23-200D | 974.83 | 8 |

Need more details? Contact us now

If you have any questions please contact us we will answer your questions via email as quickly as possible.